Industrial metal detectors delivered worldwide

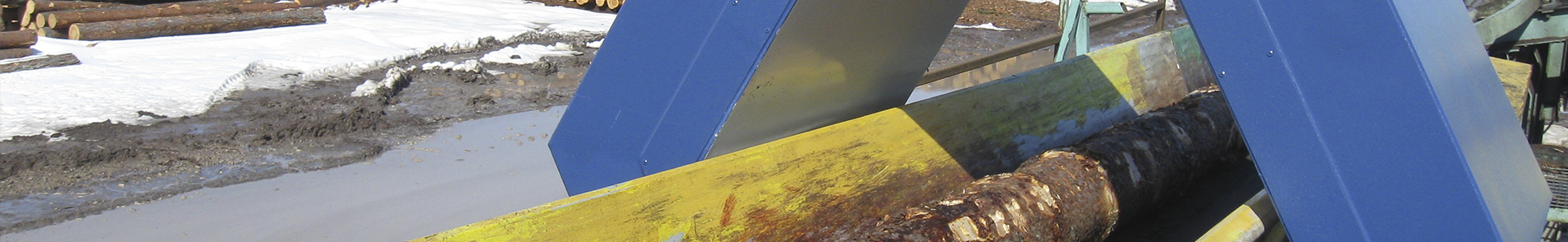

The MD500 metal detector seamlessly integrates the proven reliability of its analog unit with a new, modernized digital unit. This hybrid approach enhances the detector's sensitivity and speeds up the identification of harmful and damaging metal pieces in raw materials or products. This combination ensures robust performance backed by cutting-edge technology, providing users in all industry sectors, such as sawmills, the paper and pulp industry, crushing plants, and power plants, with an indispensable tool for detecting both magnetic and non-magnetic metals like nails, screw threads, shards, chains, metal chips, bottle caps, and aluminum foils., etc.

This advanced digital technology not only improves sensitivity but also facilitates easier troubleshooting with straightforward fault code checks and enhanced integration into industrial infrastructure. Implementations can include streamlined connections to existing operational systems and improved data communication protocols.

Furthermore, the MD500 now supports IoT (Internet of Things) capabilities for remote monitoring, which allows for the collection of valuable data such as product interruption reports and quality assessments. This IoT technology can be integrated into customers' internal networks and private cloud environments, offering a comprehensive suite of benefits tailored to modern industrial needs. By default IoT working with mobile connection to Metaldet cloud but it is also possible integrate to customer private cloud or server room. Please ask more details.

Magnets continue to remove part of the metals, but not non-ferrous metals such as aluminum, copper, and stainless steel. However, the MD500 remains an indispensable measuring device for protecting products and production machinery from the damages caused by excess metal objects and production interruptions. The device is fully automated and easy to use. For more detailed information or specific queries, please contact us for further assistance.

The Metal Detector MD500 consists of a Basic Unit DB1 and a Detector coil

BASIC UNIT DB1

The base unit's cover of the MD500 features a green operation LED and a red detection LED. When metal is detected, the red LED illuminates, signaling an active alert, and the alarm relay activates. This relay can be connected to an external indicator light, an alarm bell, or a light to visually or audibly alert operators. Additionally, it can control further operational functions, such as stopping the conveyor or operating the ejector and marking devices, based on inputs from the digital unit.The digital unit of the MD500 enhances these functionalities by providing outputs to industrial logic controllers. It issues alarms when metal is detected, signals a fault if there is a possible failure in the DB1 unit, and indicates when the device is ready to detect. This allows for real-time decision-making in a Programmable Logic Controller (PLC), enabling automated responses based on the current status of the device, such as taking preventive action when the device is not ready to detect or responding immediately when metal is detected.After detecting metal, the device automatically returns to a ready-to-use status once the metal piece has been removed. Alternatively, it can be manually reset using the reset button. This ensures that the MD500 remains a critical component in maintaining operational efficiency and safety in industrial settings.

The device’s detection sensitivity can be adjusted according to the purpose of use. Only high-quality, tested components have been used in the electronics of the MD500 metal detector. Particular attention has been paid on the heat and frost resistance of the device.

The basic unit has been installed in a watertight steel casing to which the cables are brought to via flange seals. The metal detector has automatic compensation circuits that keep the device accurately calibrated in case of temperature and moisture level fluctuations.

The metal detector is extremely easy to maintain since all the units are effortlessly accessible. Electronics have been distributed in to several separate and replaceable injection units. All the most important units include a measurement circuit which is connected to the test meter located at the front panel. Potential faults are located with the test meter and the faulty injection unit is replaced with a new one.

Options

IoT Integration: The MD500 can be equipped with IoT capabilities, allowing for remote monitoring and management. This feature enables the collection and analysis of real-time data, such as product interruption reports and quality assessments. IoT technology can also be seamlessly integrated into customers' internal networks and private cloud infrastructures, enhancing operational efficiency and proactive maintenance.

Rain Detector: An optional rain detector can be installed to adjust the sensitivity of the MD500 automatically. When rain is detected, the system reduces its sensitivity to mitigate the increased interference caused by water. This adaptation ensures more stable and reliable metal detection performance in wet weather conditions, preventing false alarms and maintaining detection accuracy.

Heater: The MD500 can be fitted with a heating unit inside the DB1 unit to combat humidity and other issues arising in cold weather. This heater helps maintain optimal operating temperatures within the detector, preventing component malfunctions due to freezing or condensation, thus ensuring consistent performance regardless of the external temperature.

Air Fan: For environments where temperatures can soar, an air fan can be added to the MD500 to enhance air circulation within the unit. This feature helps keep the internal components cool, ensuring that the device operates effectively even in high heat. The air fan is designed to prevent overheating, preserving the longevity and reliability of the detector.

Twin Detector: Incorporating twin detection technology, the MD500 utilizes two different coils to enhance its sensitivity and detection capabilities. This dual-coil arrangement allows for finer discrimination of metal types and sizes, improving the overall accuracy and efficiency of the metal detection process. The twin detector option is ideal for complex industrial applications where precision is paramount.

Colour Marking Device (CM1/B): The colour marking device CM1/B can be connected to the MD500 metal detector to mark detected pieces of metal. This device includes a pressurized ink tank, a pressure controller, a solenoid control valve, and modernized digital automatic spray guns. Up to two digital spray guns can be connected to the device, enabling precise and visible marking of contaminated materials as they pass through the detection process. These modernized spray guns enhance the accuracy and efficiency of the marking process, making them ideal for sorting operations and quality control by providing a clear visual indication of detected metals for subsequent removal or inspection.

Other auxilliary devices

Glass fibre trough

Alarm bell

Alarm light

Reset button

Track pulse sensor

Color

Cables